AZAD HARDWARE |

|

| We deal with Quality Hardware Goods, Door Locks, Door Closer,

Floor Springs, Drawer Slides, Auto Closing Hinges & All

Kind of Furniture Fittings |

|

AZAD STEEL |

|

|

TATA Tiscon TMT bars: Thermo Machanical treatment of steel bars.

Tata Tiscon is made from pure steel, with the most advanced TMT technology

from Tempcore, Belgium in the state-of-the-art plants of Tata Steel. Tata

Tiscon rebars are 'hot rolled' in fully |

|

AZAD & CO |

|

|

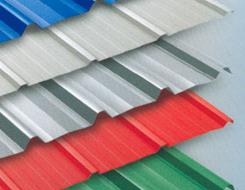

| We are wholesale dealers of quality thermal insulated products such as glass epoxy sheets, FRP epoxy sheets, insulating glass epoxy sheets, FRP sheets,Transperent fiber roofing sheets,HDPE rolls and many more of reputed companies like Phinolex and lotus. |

|

|

|

|

|

| |

AZAD HARDWARE - TATA Steel Wire |

| |

THE NEW NAME FOR QUALITY

Special Steels Limited was set up in 1958 to manufacture steel wires. Being pioneers

in the field spurred the company to establish and maintain the highest standards of

quality.

1984 was a milestone in the history of the company when it became

a part of the TATA family, reinforcing itís quality and commitment through the TATA

culture.

In 1996 the company formally became Tata Wire Division, with an

annual manufacturing capacity of 150,000 Metric Tons of steel wires and the largest

galvanising capacity in the country (40,000 Metric Tons per annum).

Tata

Wire Division has set up state-of-the-art galvanising lines at its Borivili

plant in Mumbai in the collaboration with Bakaert, Belgium to confidently

meet the projected demands and challenges of the next millennium. |

|

|

| |

|

|

| |

|

|

|

|

|

TOMORROW’S TECHNOLOGY… TODAY

Our galvanised wire has uniform zinc coating with wax coating option,

enabling the end users to produce better quality finished products. The wire

can be supplied in one ton orbit wound pattern laid coils. High speed payouts

upto 120 meters per minute is possible thanks to the special honeycomb shaped

windings. Each coil is robust and signode strapped at four places.

The major advantage in using one ton orbit wound pattern laid coils is the

substantial increase in productivity due to higher payout speed and fewer

stoppages. There is saving in

space as orbit wound coils are compact, easy to handle and can be stacked on

their sides, one on top of the other.

Coils are produced in one ton orbit wound pattern laid conditions. These

are then weighed as per the customers requirements and cut to the desired weight

on the automatic coil cutting machine. The coils are then compacted and signode

strapped.

What’s more, orbit wound pattern laid coils have no core or spool

to be disposed of. |

|

|